Electrostatic Spraying Systems

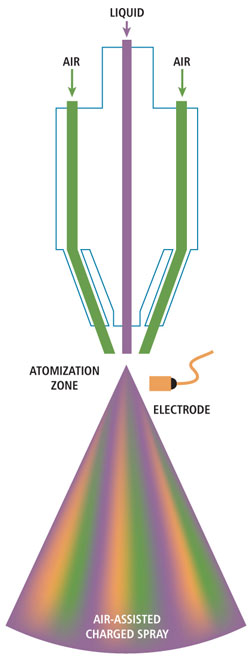

But just what is “electrostatic” technology? At the tip of the ESS nozzle is a tiny electrode which applies an electrical charge to the spray. This electrical charging causes a natural force of attraction between the spray droplets and target surface, similar to the attraction between items of clothing created by the tumbling of a clothes dryer. The charge on the droplets is small, but the force pulling the spray towards the target is up to 75 times greater than the force of gravity. Droplets literally reverse direction and move upwards, against gravity, when passing a target surface. This remarkable phenomenon by which the spray coats the undersides and the backsides of the spray target is known as electrostatic “wraparound.” In practical terms, this means that spray reaches the underside, the back side, and nooks or crevasses of the target surface. more

What is “electrostatic” technology?

Size Matters

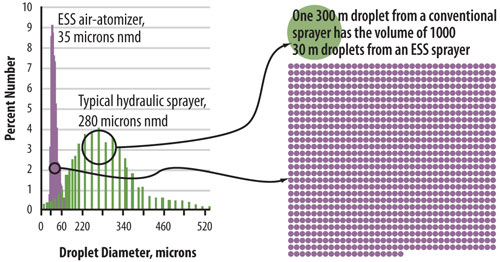

None of this would be possible if the droplets were the size of those produced by conventional sprayers. Air-assisted electrostatic sprayers manufactured by ESS produce spray droplets which are 900 times smaller. The tiny droplets are blown toward the spray target in a highspeed air stream (the “air-assist”). The result is more than twice the deposition efficiency of other non-electrostatic air-assisted sprayers.

Spray coverage is the uniformity of spray droplets on target surfaces. Electrostatic sprayers achieve greater spray coverage by combining air turbulence with tiny, evenly-sized spray droplets. Dense coverage on the back and underneath results from electrostatic wraparound. The goal is to achieve an even coating with the disinfectant chemical. If the coverage is spotty or incomplete, chances increase that dangerous infective organisms will survive. With an electrostatic sprayer, the benefits are clear: Disease control is better because the chance of contact with the disinfecting chemical is greater.

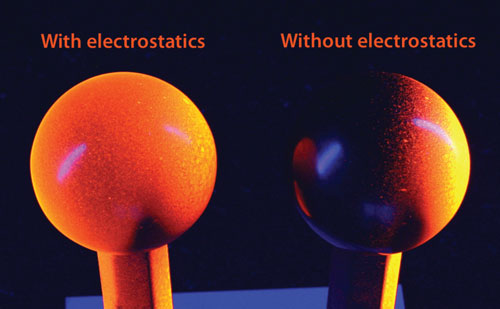

See The Difference For Yourself!

The black knob on the left was sprayed with fluorescent dye and with the electrostatic system turned on. However, the knob on the right was sprayed with the electrostatic system off. The spray coverage is so uneven that the back side of the knob remains untouched and is actually able to reflect the evenly-coated electrostatic knob.

Take a look at the two ceramic test targets below. Each were sprayed under the same conditions, with the exception of one thing...

- Safer for workers, students, and others in the area: Low volume electrostatic spraying means less chemical exposure for everyone.

- More effective: The small droplet size and improved coverage sub-stantially improves the bioavailability of disinfectant compounds.

- More effective: The small droplet size and improved coverage sub-stantially improves the bioavailability of disinfectant compounds.

- Less toxic chemicals can be used: The increased effectiveness allows more choices for disinfection and sanitization.

- Better for the environment: By using safer chemicals and reducing waste, the total environmental load is substantially lightened.

Benefits of Electrostatic Spraying

Electrostatic Sprayer Models

(Click on a sprayer model for product information)

Our Electrostatic Sprayers use electrostatic technology that produces the highest spray transfer efficiency of any sprayer on the market. The numerous benefits of using electrostatics when applying liquid solutions are not limited to sanitizing, disinfecting, and odor control applications. The superior technology and versatility of electrostatics has extended these same benefits to entirely new industries who may have never considered using electrostatics before.

ESS Industry Applications

- Agriculture

- Applying Solutions to the Human Body

- Sanitizing Facilities

- Food Processing

- Decontaminating Equipment and Personnel

- Transportation

- Medical Facilities and Devices

- Pest Control

- Manufacturing